| PRODUCT CATEGORY | Fuel |

FEATURES

- The main power spool is accurately positioned by the unbalanced pilot spool to reduce stalling and boost efficiency.

- Durable diaphragm construction guarantees a longer operational life and constant performance.

- A unique exhaust chamber including two silencers to increase diffusion pathways, lessen icing, and guarantee a low decibel level.

- A unique pinch clamping mechanism that reduces wear and extends the diaphragm's lifespan while creating a consistent seal to prevent leaks.

- Pneumatic exchangers are readily accessible from the outside for a brief examination.

- For long-term leak-proof operation, the entire design is fastened for an efficient sealing.

- Plastic air valve and solid polypropylene air chambers provide the highest level of chemical resistance in extremely corrosive conditions.

- Long valve life is ensured by the acetalic shuttle and auto-lubricated material.

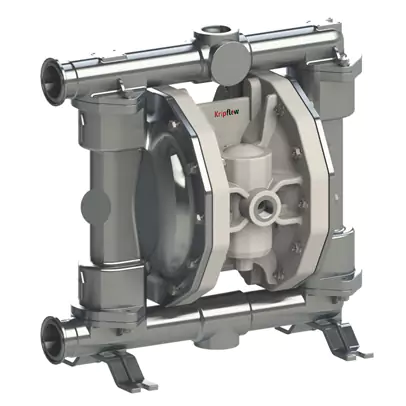

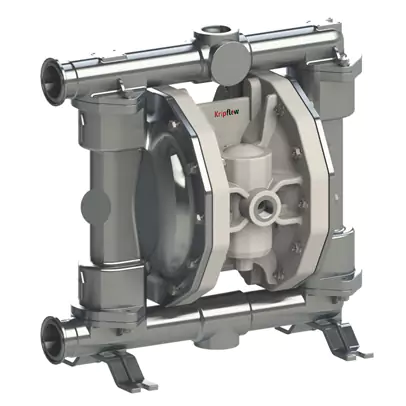

DESCRIPTION

It has long been known that air-operated double diaphragm pumps are the most adaptable in the business for managing challenging liquids at comparatively low pressures and flows. There are essentially an infinite number of applications. Italcom AODD pumps are available in a variety of sizes and construction materials. It is possible to pump almost any kind of liquid, including highly corrosive chemicals, paints and adhesives with high viscosities, and food and drink items.

Technical Data

Specifications

PF100

- Fluid connections: Tri-clamp 1"

- Air connection: 3/8" BSP

- Max flow-rate: 110 It/min

- Max air pressure: 8 bar

- Max Viscosity: 25.000 cps

PF160

- Fluid connections: Tri-clamp 1" 1/2

- Air connection: 1/2" BSP

- Max flow-rate: 170 It/min

- Max air pressure: 8 bar

- Max Viscosity: 35.000 cps

Performance Curve

Dimension

Composition

| Model | Casing | Diaphragm | Balss | Seats | Gasket | Connections | ATEX | Ports |

|

PF100 PF160 |

S = SS POLISHED |

HT = HYTREL+PTFE |

T = PTFE S = SS |

S = SS |

T = PTFE |

1 = BSP 3 = TRI-CLAMP |

- = zone 2 X = zone 1 |

AB = STANDARD |